Is Lone Worker Safety Right for You?

Identify

-

Automatically count personnel at muster stations and quickly locate missing personnel.

-

Integrates with existing systems to ensure your employees' safety is part of your larger facility strategy.

Locate

-

Know exactly where your employees, visitors, and contractors are at any time.

-

Tag options include low-profile, simple location monitoring tags, tags with call buttons, and sophisticated Staff tags

Protect

-

Provide prompt assistance to staff in isolated environments via a simple button press.

-

Real-time emergency roll-call at muster stations.

Why GuardRFID® for Lone Worker Safety?

The most advanced real-time asset tracking solution offering the smallest, toughest, and longest-lasting tags in the industry plus long-range presence detection.

-

Prevent Worker Injuries

Lower operational costs by preventing worker injury while providing a safe environment for workers to thrive within.

-

Multiple duress alarm messaging options (e.g. workstation alarms, email, mobile client, CCTV, voice messaging)

-

Configurable tag buttons, two-way communications & programmable Man Down alarm capabilities

-

-

Gain Real Visibility

Gain real visibility at any given moment through an intuitive software “dashboard”.

-

Long-range real-time location & perimeter security in a single enterprise-wide system

-

Strongest immunity to wireless interference with zero impact on or from Wi-Fi networks

-

-

Integrate With Existing Safety Systems

Integrate with existing safety systems to ensure your personnel protection is part of your larger facility strategy.

-

Seamless integration with existing IT policies, standards & worker safety systems

-

Feature-rich, user-friendly software with centralized monitoring across sites

-

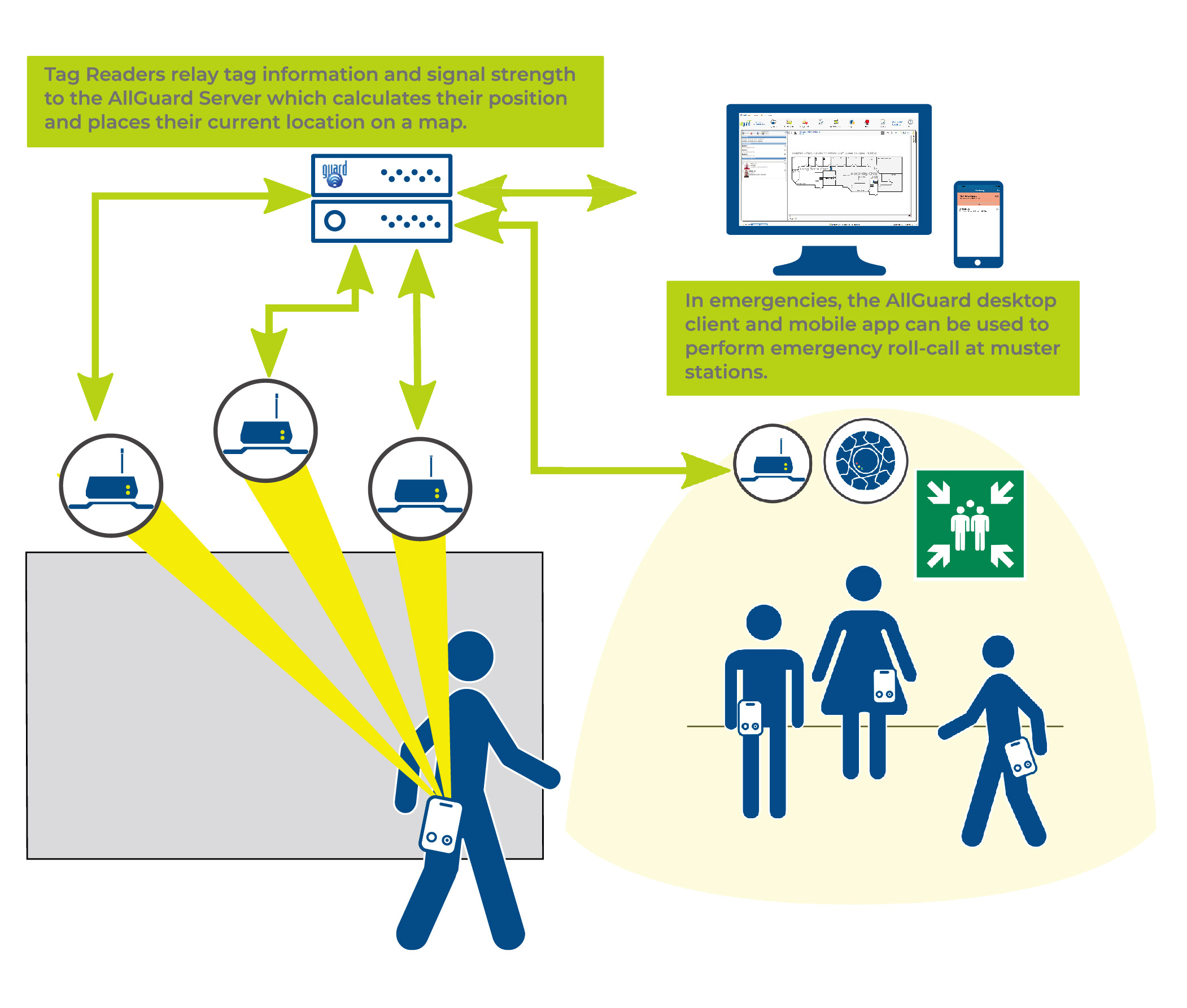

How RTLS for Lone Worker Safety Works

Ensure real-time safety for personnel in industrial environments and remote locations

Personnel are assigned an active RFID tag with optional call button support — this can be attached to hardhats, worn on a wristband, or attached to a lanyard. The solution uses the GuardRFID suite of infrastructure hardware and AllGuard® enterprise software to provide real-time location monitoring, activate alarms, and mustering support. If personnel press the call button on their tag, the active RFID tag raises an alarm in the AllGuard software. When the alarm is received in real-time, the software can identify where the worker is and send help to investigate the emergency situation.

Is Lone Worker Safety Right for You?

Related RTLS Products

Hazard-Rated Industrial Tag (IT-2-EX)

Hazard-Rated Personnel Tag (PT-3-EX)

Article Tag (AT-4)

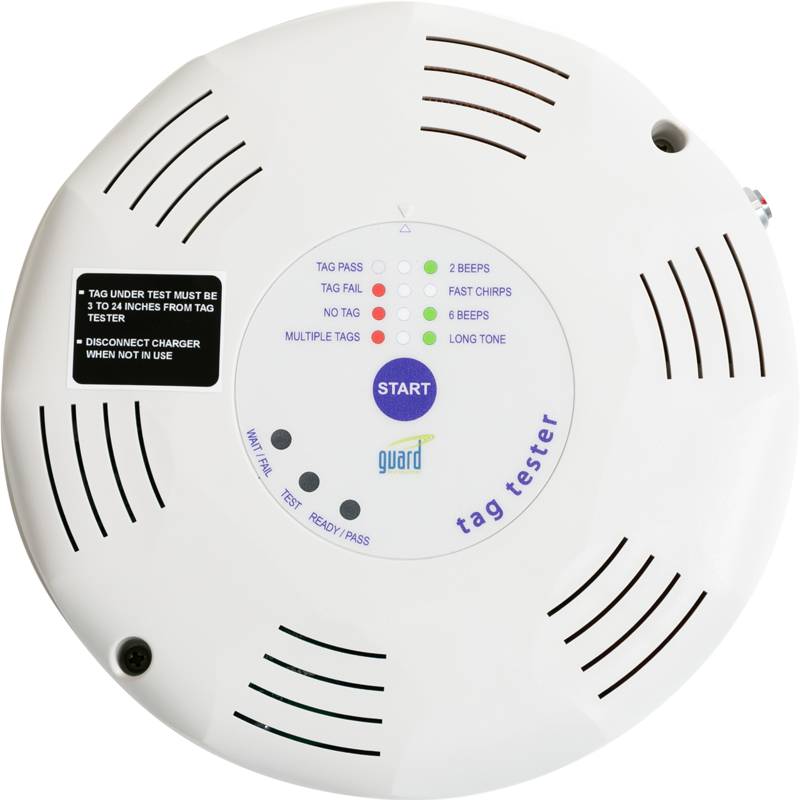

Portable Tag Tester